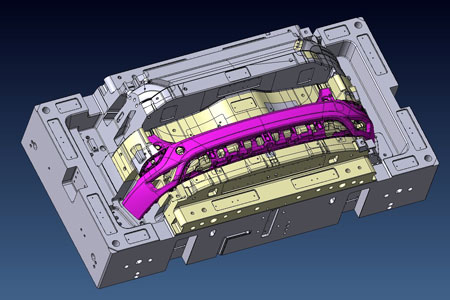

Mould design and plastic parts

Development of your product

- Our Auchel and Blangy engineering offices with a dozen technicians are able to develop and scan your parts from your sketches or models

- We manage the prototype parts and prototype injection mould phases with simultaneous engineering

- We are able to improve the feasibility of your projects and then to industrialize a process

- Manufacture of plastic parts of appearance and techniques in the field of automobiles, household appliances, packaging, luggage….

Study of production and control tools

- Years of experience allow us to put at your disposal ever more extensive skills:

- Mould design guided by our technical libraries, by the rheology, the economic analysis the technical standard of the client…

- Our skills extend to injection moulds, compression, cutting and stamping tools, but also to inspection tools and precision engineering thanks to our MDM subsidiary based in Maubeuge.

- Tracking grain and treatments

Our technical means of digitizing and creating prototypes

Our software

- CATIA V5

- THINK DESIGN 2009.3

- HYPERCAD

- HYPERMILL

- WORK NC

- GOELAN V5

Our other media for palpating and scanning surfaces

- Three dimensional STIEFELMAYER 3d 2440x1200x1500 mm

- Three-dimensional Zeiss 3d 700x700x600 mm

Our means of modeling

- We have a POLYJET 3d printer to produce polymerized resin prototypes.

Production of appearance and technical parts in the field of automotive, household appliances, packaging, luggage storage…

Archiving of plans, DFN Secure/ISO 9001 V2008.